Define the scope for implementation and set the goals.

Version 1 - Last updated -

A supplier should first define the scope for implementation. Once that is determined then set the goals for that scope.

Defining scope

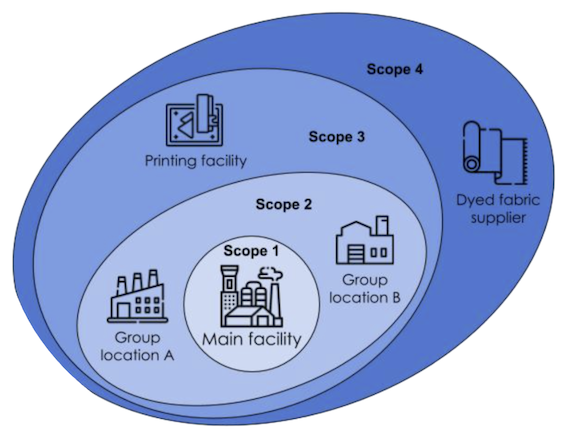

A supplier’s defined scope coverage can be:

- Main facility that includes all operations on site.

- Multi-locational facilities (if applicable).

- Immediate level of upstream sub-suppliers/subcontractors.

- Next level of upstream sub-suppliers/subcontractors

| Scope 1: | The main facility |

| Scope 2: | The main facility + group facility location A and location B |

| Scope 3: | The main facility + group facility location A and location B+ printing facility (immediate sub-supplier) |

| Scope 4: | The main facility + group facility location A and location B+ printing facility (immediate sub-supplier) + dyed fabric supplier (next level of sub-supplier) |

Setting Goals

The goals to be set for each scope should be ‘SMART’ (Specific, Measurable, Achievable, Relevant and Time-Bound) and should be tracked for implementation.

Each goal should be translated into the action plan for implementation that details the methodology and timeline.

Examples of goals for chemical management:

- To prepare a chemical inventory list

- To achieve x% of ZDHC MRSL conformant input chemicals

- To implement an emergency response plan

- To provide PPE for all workers

- To train all staff on chemical management topics

- To engage with x% upstream suppliers for ZDHC Supplier RtZ implementation